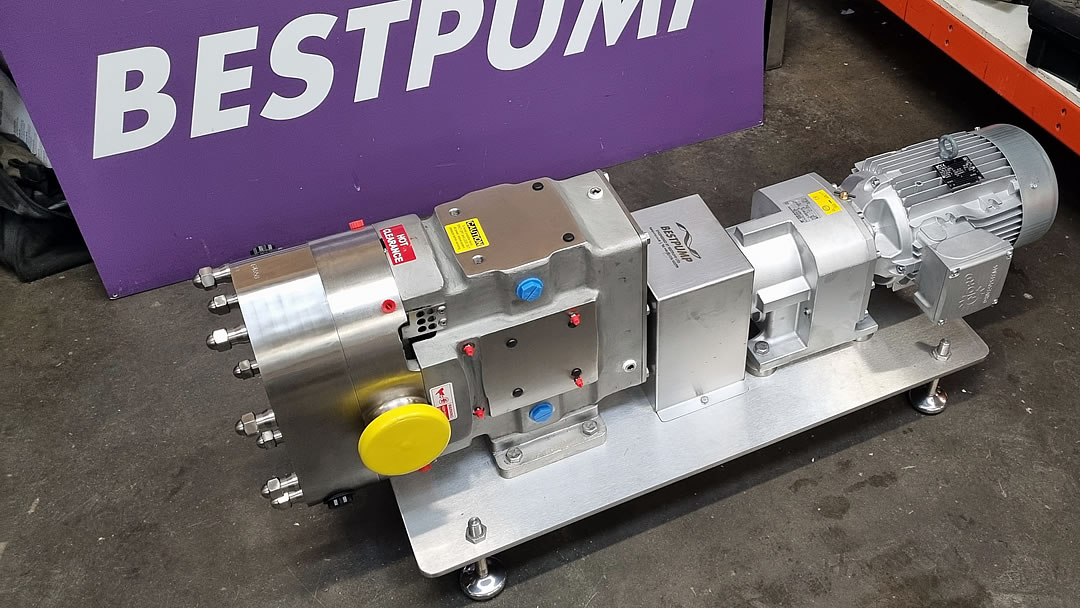

Hygienic chocolate pump supplier, BestPump Ltd, of Coatbridge, UK was commissioned to engineer this hygienic stainless-steel circumferential piston pump motorised assembly.

The end user, a chocolate manufacturer that everybody knows, had historically been a user of the Waukesha Cherry Burrell Universal 1 pump series but, many years ago, made the decision to convert to the interchangeable Viking Pump Hygienic TRA10 series.

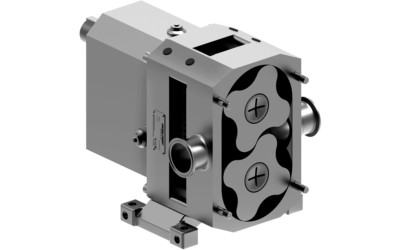

They continue to add to their hygienic pump fleet with this latest purchase – a TRA10 0600 2½-inch model.

The pump is constructed from 316 stainless-steel and features a jacketed cover to maintain product temperature.

The gear case is constructed from 304 stainless-steel and this is now the standard for this manufaturer (no more flaking paint from ageing gear cases).

The TRA10 series offers four choices of seal type:

- Single O-ring seal

- Single mechanical seal

- Double O-ring seal with flush

- Double mechanical seal with flush

The standard materials for these seals are:

O-ring seals

Elastomers in Buna FDA, EPDM FDA, FKM FDA or Silicone FDA.

The o-ring seal arrangements feature shaft sleeves and the sleeve material options are stainless-steel, Zirconia or Chrome Oxide.

Mechanical Seals

Elastomers in Buna FDA, EPDM FDA, FKM FDA or Silicone FDA.

The standard seal face material options are Carbon, Ceramic, Silicon Carbide or Chrome Oxide.

Tungsten Carbide Mechanical Seal Faces for TRA10

BestPump offers the non-standard option of Tungsten Carbide seal faces for both single and double mechanical seals on these pumps.

We can supply these on new TRA10 pumps or upgrade existing TRA10 or Waukesha Pumps Universal 1 series models.

Pump Requirement

For this particular project, the pumping parameters were as below.

| Fluid | Cocoa Liquor |

| Viscosity | 1,000 centiPoise |

| Temperature | 80°C |

| Pressure | 1.7 bar |

| Flow Rate | 4.5m³ per hour |

Hygienic Chocolate Pump

The industry’s best chocolate products deserve the best hygienic pump.

This Viking Pump, Inc. hygienic TRA10 0600 circumferential piston pump features a heated cover, chocolate clearance rotors and, at the client’s request, we retro fitted Tungsten Carbide seal faces with FKM o-rings.

With a NORD Gear Corporation geared drive and all mounted on a bespoke stainless-steel baseplate engineered and assembled by BestPump Ltd, this is a really good example of a top notch chocolate pumping solution.

Now, onto the next Hygienic pumping solution….