Dairy processing equipment

Dairy processing equipment for butter, spread & margarine

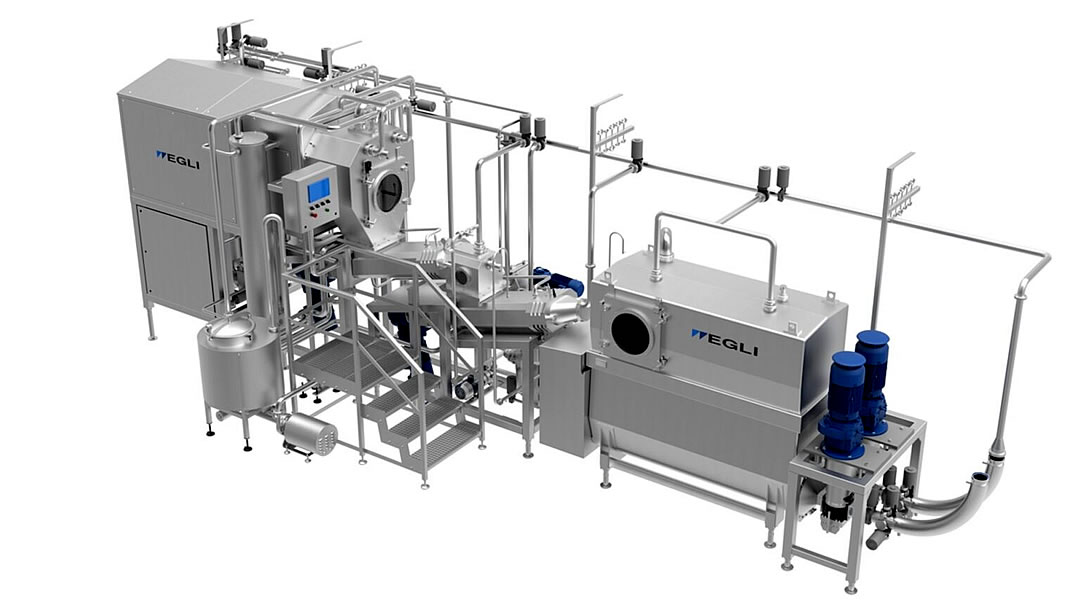

Butter Making Machine

Model EKB

The EKB is capable of continuous manufacturing of butter up to 10,000 kg per hour and is suitable for cream with a fat content of 32% to 45%.

The system consists of a churning section, a separation section, a working section no.1, a vacuum chamber & a working section no.2.

Constructed from stainless-steel with level adjustable feet and frequency-controlled drives, the EKB butter making system is designed to have low vibrations and easy maintenance.

Butter Silo provides buffer storage and is essential for a flexible and continuous butter production process. The silo is typically completely enclosed and located between the production system and the butter packaging machine or reworking line. Silo capacity can be up to 7,500kg.

Other options:

Open Silo with pneumatic sliding cover.

Open Silo with swing-up cover.

Open Silo without cover (silo can be fitted underneath churns, butter shredders etc.

Butter Pump to transfer butter from silo to packaging machines. Runs at low rpm to ensure gentle-handling of the product. Pump is CIP- ready (clean in place), features rotors of either bi-lobe or tri-lobe design and uses FDA approved seals.

Butter Churn

Model EBF

Stainless-Steel butter churn capable of producing batches of 100 to 15,000 litres of homogenous traditional butter. CIP-ready.

Dry kneading option available for higher capacities.

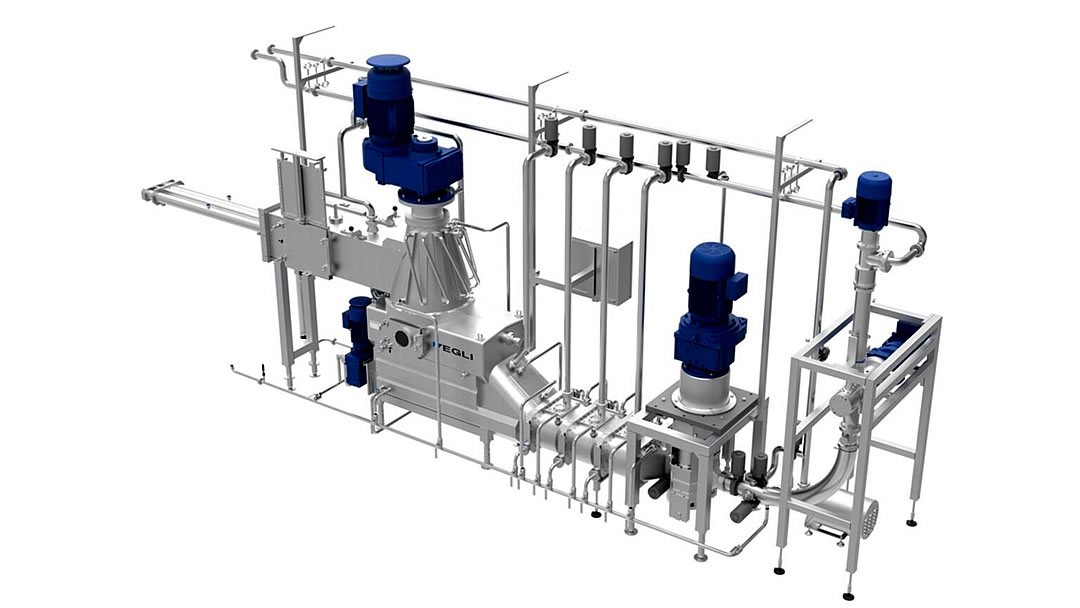

Butter Reworking Equipment

Butter Reworker Model EBR

As well as butter manufacturing equipment, Egli AG also supplies butter reworking equipment. If your blocks of butter are delivered frozen or are stored frozen, there is no need to wait days on tempering – simply rework it from -20°C!

The butter reworker system converts 20kg & 25kg frozen or tempered blocks of salted and / or unsalted butter into a softer, easy-to-spread consistency.

The butter blocks can be loaded at a temperature as low as -20°C or as high as +10°C and are processed gently and econonomically.

With a capacity of up to 10,000kg per hour the EBR also has a dosing function for the introducing of flavours and ingredients e.g. vanilla, aroma, herbs, honey, salt (fluid or dry), culture, additional moisture etc.

The EBR can be cleaned by CIP (clean-in-place).

Butter Block Shredder

Model EBS

This conical block shredder is capable of reducing frozen butter bulks & blocks into small pieces.

The frozen butter blocks are safely transported to the shredder by a feeding tunnel which features a suitably-szied hinged door and a pneumatic feeding mechanism. The small, shredded pieces collect below the conical shredder and can then be transported to the next stage of your process.

The EBS is suitable for blocks at a temperature as low as -20°C and it has a capacity range of 500 – 10,000kg per hour. CIP-ready.