Screw feeders that enable pumping of highly viscous products

Step 1

Load Viscous Products

Load product into the hopper manually by gravity or automatically by conveyor

Step 2

Process & Prime the Pump

Auger screws process the product then prime and feed the pump’s enlarged suction port

Step 3

Pump High Viscosity Products

Heavy duty positive displacement pump discharges viscous media

Pump feeders for pumping solids, high viscosity pastes & products that do not flow

BestPump manufactures hygienic food-grade pump feeders that make it possible to process and pump high viscosity, non-flowing and heavy products that cannot be pumped using only conventional pumps.

Our screw feeders (commonly called auger feeders) provide a positive feed of your heavy, viscous products into a positive displacement pump. The screws are suitable for handling bridging products, viscous products and other products that do not flow.

Not only does our high viscosity pump feeders allow you to pump viscous products, they also improve pump performance, increase pump efficiency and maintain pump prime to ensure continuous, steady flow.

Check out the information and videos below to see us successfully pumping products which cannot be pumped on their own using standard pumping methods.

Pump feeder video

Skip to the good parts

0:19 – Fig Paste discs

0:51 – 12½ kg Blocks of hard shortening

0:56 – Golf ball test

1:51 – Concentrated Sticky Fruit Paste

3:02 – Concentrated fruit cubes

3:25 – Moist, flaky materials

3:47 – Bouillon (de-hydrated stock)

5:25 – 25kg butter blocks straight from the chill at 3°C

6:15 – Extruding sheets of butter

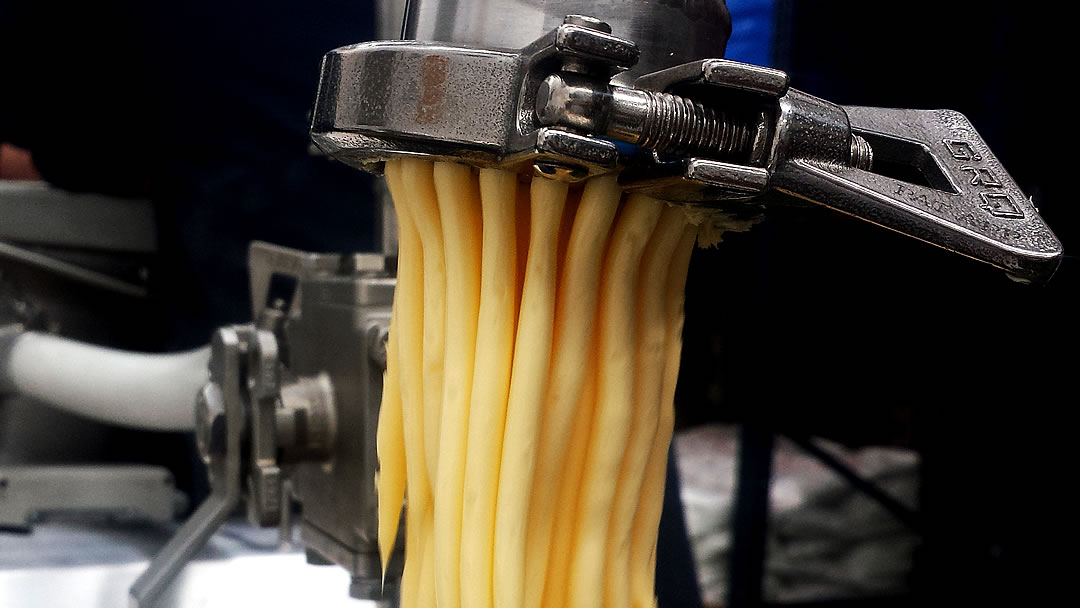

6:30 – Fat blocks extruded in 1mm strands for reduced mixing times

6:49 – Batching ingredients directly into mixers

What can we pump?

Typical Applications

- Solid Fats

Butter, cheese, margarine, shortening, shea butter, palm oil, soya bean oil, frozen chicken fat - Pastes

Fig paste, date paste, dehydrated stock / bouillon, proteins - Sticky products

Caramel, fruit concentrates, pastry dough - Meats

Pet food, minced meat, processed fish - Creams

Cream cheese, cosmetics, peanut butter, cream fillings - Chocolate

Dark, white & milk chocolate bulk reduction

Bulk butter blocks handled simply and safely with pump feeders

Convert hard butter blocks to soft butter 'on tap'

BestPump’s pump feeder systems can convert cold hard butter blocks into soft, spaghetti-like strands that are lump-free and ideal for mixing.

The system can deliver set batch sizes or run continuously with minimal human interaction.

Simply load the conveyor with your product e.g. butter, cheese, margarine or shortening (typically supplied in 10, 12 or 25kg blocks) and the machine will deliver the batch inside the time period you specify.

- Typical flow rates from 5 to 150kg per minute

- Temperature is product-dependant but we can handle butter from 1°C+ and some shortenings can be pumped from frozen

Pump feeder with conveyor

Conveyor automatically deposits next block of product into the hopper when the control system demands.

Using a touchscreen interface, the control system allows for batching, pump control, screws control. External signals from load cells, flow meters and such can be added for sophisticated performance.

The hopper with safety guard receives the raw product from the conveyor. The product drops into the screws at the bottom of the hopper.

The heavy-duty positive displacement pump with enlarged inlet port is positively fed by the screws. Viscous media enters the pump inlet and is then discharged through the pipework.

Pipework can be a short arrangement for loading mobile vessels or it can be a significant length to deliver your product directly into mixers, kettles and other vessels.

Pump feeders for multiple production lines

Pump to multiple remote locations simultaneously with a multi-pump screw feeder

Dump bulk batches of freshly made cream, peanut buuter, cream cheese & other viscous products then rapidly pump them to remote filling lines or depositors.

Deliver multiple streams of product at different rates consistently and without air pockets. Batching, metering & dosing capabilities as required.

Our screw feeders are typically designed and manufactured to specific customer requirements and sometimes to integrate with existing machinery such as mixers.

We found that a large hopper system is ideal for rapid transfers of freshly mixed bulk batches from mixers.

Upgrading from a single pump system to multiple pumps gives huge potential for increasing productivity.

Clients can perform ultra-fast pumping of high viscosity products direct from a mixer to different locations around their plant and they can do so simultaneously with multiple pumps running at variable speeds.

Frequently Asked Questions

What is a pump feeder?

A pump feeder is a solution made up of screws, hopper and a pump and is designed to remove the many headaches associated with processing and pumping heavy, viscous and awkward solid, pasty, chunky, lumpy or sticky ingredients.

The solution enables the pumping of solid and highly viscous materials that cannot be pumped using conventional pump technology.

How and when did BestPump develop the technology?

The concept dates back to 2004 when a bakery tasked BestPump with upgrading their historic methods of labour-intensive manual lifting, cutting and weighing refrigerated 25kg blocks of butter.

We installed a solution that re-worked the butter blocks straight from the refrigerator and enabled the client to pump accurate batched weights of plasticised, consistent, lump-free butter directly into their mixers on demand – they literally ended up with smooth cold butter on tap!

We have developed the screw feeder and pump concept further and it is now used for many different solids and viscous fluid handling duties.

Why did BestPump develop pump feeders?

We saw many food manufacturing clients facing the same headaches when working with bulk ingredients that are either in solid form or are highly viscous and unable to flow naturally into a pump.

These ingredients need to get into the production line but if there is no obvious automated solution then it needs to be a manual, labour intensive process.

We see the demands being put on operatives as they lifted heavy blocks, scooped dense pastes, cut solids into small pieces or even shovelled thick creamy products!

With a BestPump pump feeder…

- Heavy lifting is reduced

- Time consuming manual transfers from vessel to vessel are no longer needed

- Safety risks when cutting solids are removed

- Wasting expensive energy to heat products in order to lower viscosity is not necessary

- Inconsistent & lumpy final mixes are eradicated

- Manual cutting and weighing becomes a thing of the past as our pump feeders can accurately dose and meter your desired batch weights

What viscous products can you handle?

The screw feeder is used for the reduction of bulk solid ingredients and the reworking of bulk solids.

The reduced or re-worked media is then pumped to the next production stage i.e. into a mixer or kettle.

We typically process and pump solid ingredients including butter, shortening, margarine, shea butter, cheddar cheese and other fats as well as caramel, chocolate, fruit concentrate and more.

The solution is also suitable for processing and transferring high viscosity pastes, concentrates, creams, slurries and other non-flowing media.

How are products loaded into the hopper?

Loading can be performed either by conveyor or by gravity.

On blocks and other solids for continuous running or batches, an in-feed conveyor is recommended to ensure that the hopper is always sufficiently filled with product.

As the hopper level diminishes, the system calls for the next block from the conveyor so all you need to do is keep the conveyor sufficiently loaded and the control system does the rest. Conveyor feeding is only suitable for blocks and other solid media.

If you are processing small amounts of block product or pumping low volumes, it is possible to load the hopper by gravity feed. In this case, the machine comes with an integrated lid or grid protected by electronic safety switches.

The hopper can be scaled up or doiwn to suit the required capacity.

For bulk loading capacities of pastes or similar, we can design a bespoke unit with enlarged hopper. This can allow the pump feeder to integrate with a mixer so you can dump a complete batch of freshly mixed product straight in and immediately start pumping it to the next stage of your process e.g. a depositor.

What flow rates can the pump feeder achieve?

To date, our highest flow rate has been 140kg of shortening per minute.

More commonly, we are asked to provide something like 15 to 30kg per minute.

The flow rate is only limited by the size of the pump used and the properties of the product being pumped.

The real question is, what flow rate do you require?

How far can the product be pumped?

This comes down to the capability of the pump selected for your particular project, the flow rate and the media viscosity.

We have successfully pumped cold butter over 40 metres from a chiller to remote mixer bays.

Sticky products typically result in significant friction losses and so discharge distances are relatively short.

Typical pressure ratings are around 12 bar but we can offer up to 35 bar when required.

What pump type is used?

We recommend circumferential piston pump or twin screw pump technology.

These pumps offer hygienic design, high pressures, shear-sensitive handling of fragile media and enlarged rectangular inlet ports for improved suction flow.

It is possible to use other pump types and we can even supply a separate screw feeder for you to attach your own pump (at client’s risk).

Can I use the system to deliver set batch weights?

Yes, with our batching function.

The touchscreen menu enables the Operator to enter the required batch weight. The system will run until the batch is delivered and then stop. Conveyor loading is recommended for this scenario.

Can the machine be controlled by level sensor, flow meter, load cell or floor scales?

Yes it can.

Simply provide an electrical signal from your measuring device to start and stop the pump feeder.

What is the temperature range?

This is subject to the materials of construction and dependent on the properties of the media to be processed.

For butter blocks, we suggest an absolute minimum of 1°C at the core of the block. We have successfully pumped other lighter fats at lower temperatures such as margarine shortening and chicken fat at -16°C.

Confectionery ingredients like chocolate and caramel can be processed at ambient temperatures.

For cheddar cheese and some concentrated fats we recommend a minimum of 2°C.

Can I try out my product to see if it works?

Yes, absolutely.

We offer video or in person trials at our premises or we can explore possibilities of testing a machine in your production areas.

This is subject to availability and may incur charges.

How do we clean a pump feeder after use?

The systems are designed for cleaning out of place and can be disassembled with a single wrench.

The screw feeder section is wheel-mounted as is the pump to give flexibility on cleaning processes.

A dedicated screw removal and cleaning trolley is supplied as standard.

Extracting the screws is a safe and simple process using the included screw extraction tool on the trolley.

After removal, the screws can be washed and re-inserted without ever having to be manually lifted.

The hopper / screw feeder housing is fitted with drains so it can be washed with hot water & cleaning fluids.

The pump, mounted on a stand-alone trolley, can be disconnected from the screw feeder and wheeled away to a wash down bay or cleaning area.

Cleaning the pump is a simple process and involves removal of the front cover then washing the internal areas of the pump rotor case.

What safety features are available?

Each machine is guarded from the conveyor hood or loading lid / grid at the top of the unit right down to the pump motor at the bottom.

If the lid is open or if any of the guards are out of place or if the pump is detached, the system is disabled.

We use sensors throughout the system to ensure that it will only operate when 100% safe.

On conveyor-fed systems, the conveyor must be correctly located in the hopper hood to operate.

Where are these made and by whom?

The design, manufacture and testing of each pump feeder is carried out by BestPump Ltd in our facility in Coatbridge, Scotland, UK.

We are a family business that specialises in distributing hygienic pumps and manufacturing stainless-steel process equipment.

Our niche is the solving of high viscosity fluid and solids handling problems – our mission is to ‘pump the unpumpable’.

Can you tell me more about BestPump?

BestPump Ltd is a distributor of hygienic pumps and a manufacturer of bespoke stainless-steel process equipment.

We have been solving customers’ tough pumping challenges since the year 2000.

With our heritage in stainless steel pumps and our reputation for innovative engineered solutions, we overcome challenges to get non-flowing products to pump and we’ve been engineering and manufacturing bespoke screw feeders since the early 2000s.

From low viscosity fluids like water and high viscosity solids like butter and everything in between, we can deliver suitable pump types including centrifugal pumps, twin-screw pumps, circumferential piston pumps, drum pumps, rotary lobe pumps, diaphragm pumps, progressive cavity pumps, peristaltic pumps and many more hygienic pump types.

Coupled to our impressive product portfolio, we have the engineering skills and the manufacturing facilities required to innovate and deliver problem-solving pump screw feeders and process systems.

If you want to know more, call us on +44 (0)1236 433799 or visit our contact page.