Hygienic Pumps

The term ‘hygienic pumps’ can have a different meaning to different people.

For some, any pump constructed from 316 stainless-steel and with food grade, FDA-compliant elastomer materials like EPDM, FKM or Nitrile would be classed as hygienic – even if the pump needed to be dismantled to be cleaned i.e. COP (clean-out-of-place)..

To others, however, a truly hygienic pump is one that, as well as being constructed in food grade materials, is also CIP (clean-in-place) and self draining with no crevices or dead-ends for product to remain and potentially decay to cause bacteria or rancidity.

Additionally, pump types that use rotating or contact wear parts made of plastics or rubbers such as impellers, stators or hoses may not be considered to be hygienic pumps by those needing to ensure product purity and avoid potential rubber particle contamination.

To that end, we present the below pumps from our industrial pump portfolio as the top pump technologies for hygienic design and cleanability.

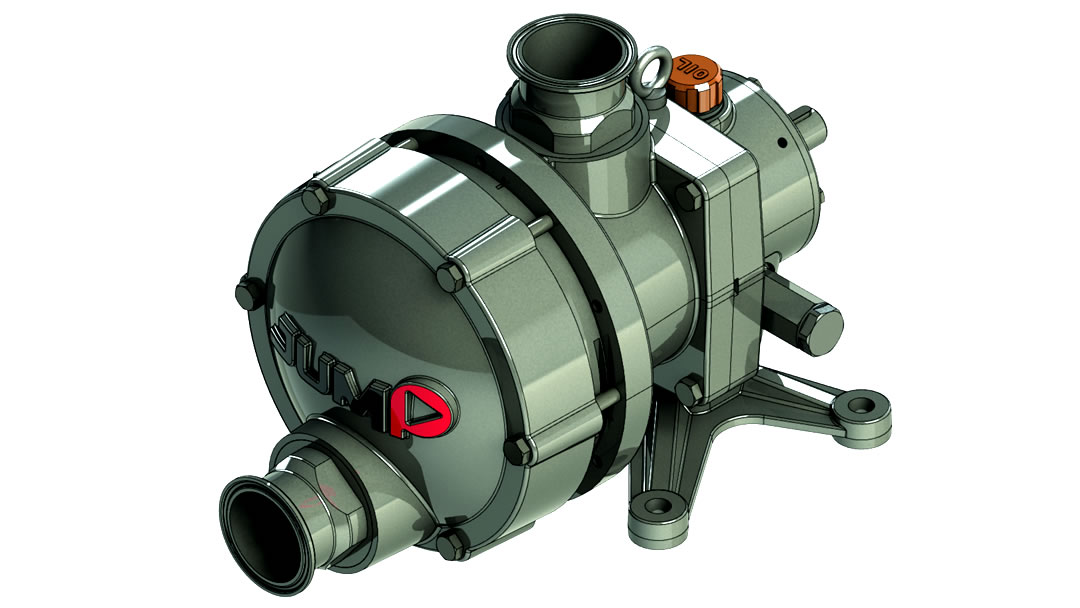

Centrifugal pumps

High volume transfer of low viscosity fluids and CIP duties.

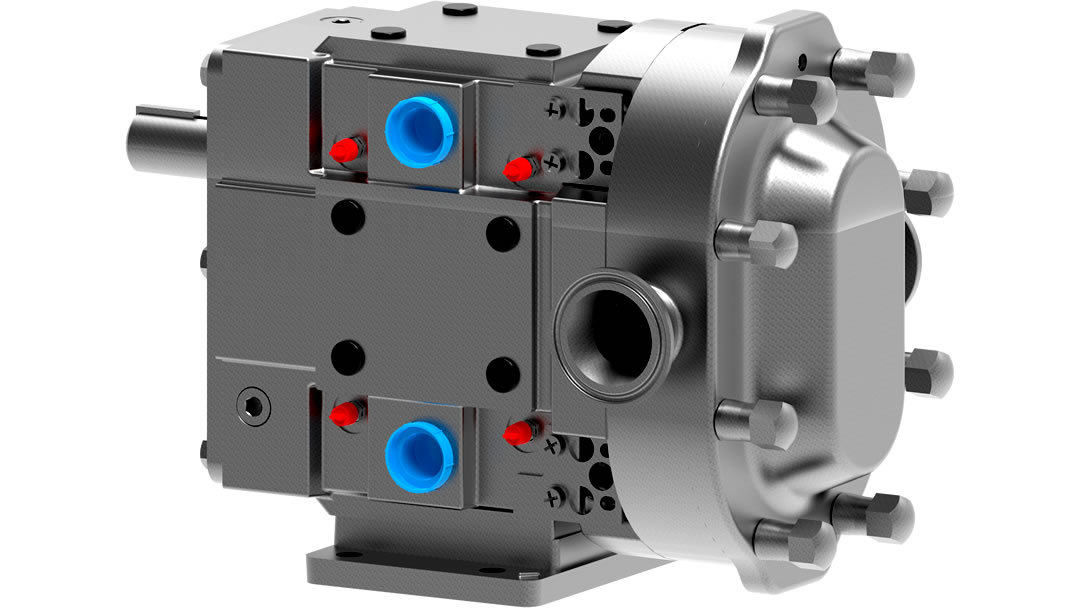

Circumferential Piston pumps

Low shear pumping of viscous fluids, fragile slurries & solids.

Diaphragm pumps

Versatile pumps with endless fluid transfer uses. Easy to use & maintain.

Drum unloaders & ibc pumps

Versatile pumps with endless fluid transfer uses. Easy to use & maintain.

Eccentric disc pumps

Strong suction, dry running and gentle handling of shear sensitive fluids.

Rotary lobe pumps

High volume, shear-sensitive transfer of viscous fluids.

Twin screw pumps

Infinite pumping of all fluid types with smooth and gentle handling.

Hygienic pumps, what are they?

Hygienic pumps are those pump types that are constructed from materials considered to be suitable for use in the production of foods, drinks, medicines, cosmetics – anything that goes in or on the body.

Clean-In-Place hygienic pumps

High-end hygienic pumps are typically constructed to be easily sanitised with self-draining, clean-in-place design (CIP) and without dead areas or crevices where product could build-up to cause rancidity and bacteria.

clean-out-of-place hygienic pumps

Some hygienic pump types need to be partially dismantled and cleaned out of place. Clean-out-of-place (COP) pumps are such because of their location, orientation or the design / pumping principle upon which they operate.