Rotary Lobe Pumps

Positive displacement pumpingRotary lobe pumps are a popular pump type for all areas of food processing, beverage, pharmaceutical and cosmetic manufacturing.

Rotary Lobe Pumps

Rotary lobe pumps use stainless-steel lobes or rotors and offer gentle handling of viscous and non-viscous shear-sensitive fluids and slurries.

These food grade positive displacement pumps feature a stainless steel 316 body and rotors.

Typical Applications

The reliability of the circumferential piston pumping principle has been proven over many decades and its heavy duty design and easy cleanability make it suitable for all sanitary fluids.

Dairy: milk, cream, curds, butter, soft cheese, yoghurt, margarine, ice-cream

Bakery: yeast, dough, fruit filling, icing, fat, oil

Meats: sausage filling, fat, broth, gelatine, pet food

Canned Foods: potato salad, baby food, soup, stew, tomato, relish, pudding, dressing, mayonnaise, jam, jelly

Beverages: beer, mash, wort, fruit juice, fruit concentrate

Confectionery: liquid sugar, chocolate, cocoa butter, cocoa liquor, corn syrup, gelatine

Flavourings: syrup, concentrate

Dressings: Mayonnaise, prepared sauces

Cosmetics: cream, lotion, jelly, shampoo, emulsion, toothpaste

Industrial: paint, ink, latex, polymer

Rotary Lobe Pump Series

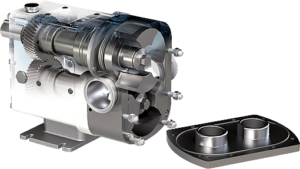

Classic Plus Series

The hygienic lobe pump designed to be cleaned out of place.

Our best-selling rotary lobe pump.

- Capacity to 102m³ per hour

- Pressure to 27 bar

- Viscosity to 200,000 cPs

- Temperature -40°C to 150°C

SteriLobe Series

The advanced hygiene rotary lobe pump designed for clean-in-place.

Popular choice for pharmaceutical manufacturers.

- Capacity to 102m³ per hour

- Pressure to 34 bar

- Viscosity to 200,000 cPs

- Temperature -40°C to 150°C

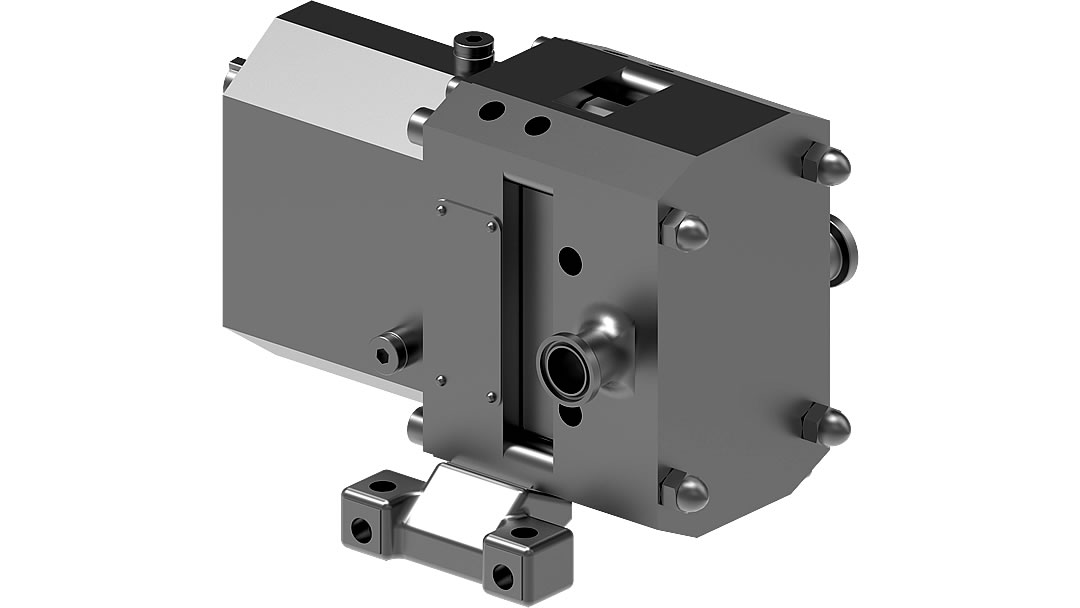

Revolution Series

The hybrid rotary lobe / circumferential piston pump.

Same exterior footprint as Waukesha® Universal 1 & 2 pumps.

- Capacity to 173m³ per hour

- Pressure to 31 bar

- Viscosity to 440,000 cPs

- Temperature -40°C to 150°C